We all want the very best value for our money; materials, workmanship, engineering, and design contribute to making a product truly great. Very often it’s the small details that most of us don’t even notice that make a huge difference. This is especially true when referring to vacuum-actuated pneumatically exhaust cutout valves which are expected to perform in a very hostile environment. Extreme temperatures, vibration, shock, moisture and the corrosive effects of road salt combine to constantly challenge the performance and ultimately durability of any exhaust valves. Watch their video here.

With 25+ years of experience designing, testing and building performance products for exotic cars, Fabspeed Motorsport uses Helical Technology Ltd. U.K. Exhaust valves imported from Great Britain exclusively in our Maxflo exhaust systems. Here are a few reasons why Helical Valves are the world’s best quality and used exclusively by Porsche, Ferrari, McLaren, Lamborghini, Aston Martin.

- Silicon Carbide Bearings: Silicon carbide is a ceramic composite material that can withstand extraordinary heat (2700 F) and has incredible wear resistance due to its hardness. This material is used in the braking systems on supercars such as the Bugatti Veyron and McLaren P1. Why is it important in an exhaust valve? Because of the bearing wears slightly the valve will rattle. If the bearing fails, your valves will be rendered useless. Low-cost valves normally include a bushing that wears quickly under normal operating conditions and often fail immediately and certainly after hard usage.

- 321 Stainless Steel: Type 321 Stainless Steel is an Austenitic stainless steel that is alloyed with Titanium. It provides excellent resistance to oxidation and corrosion and can withstand temperatures of 1500F. Why is it important in an exhaust valve? Because if the moving parts inside your valve corrode or deform due to heat, the valve will eventually get stuck and become inoperable. Another failure point.

- Airflow: The inside walls of the valve are designed with a gradual taper to reduce surface boundary layer airflow friction and improve flow. Why is this important in your exhaust valve? Because increased friction will result in less than optimum flow and ultimately less performance from your car.

- Continuous diameter actuator shaft: The large-diameter actuator shaft and clevis end are formed as 1 piece for maximum strength and fatigue resistance. Why is this Important in your exhaust valve? Because the actuator shaft is under constant cyclic loading and prone to failure if improperly designed. This is a common failure point for inferior quality valves.

- Diaphragm Mounting: The Helical mounting bracket and valve body are cast as one fully integral piece. Why is this important in your exhaust valve? Because misalignment of the diaphragm from a low strength mount will cause your valve to bind and become unresponsive.

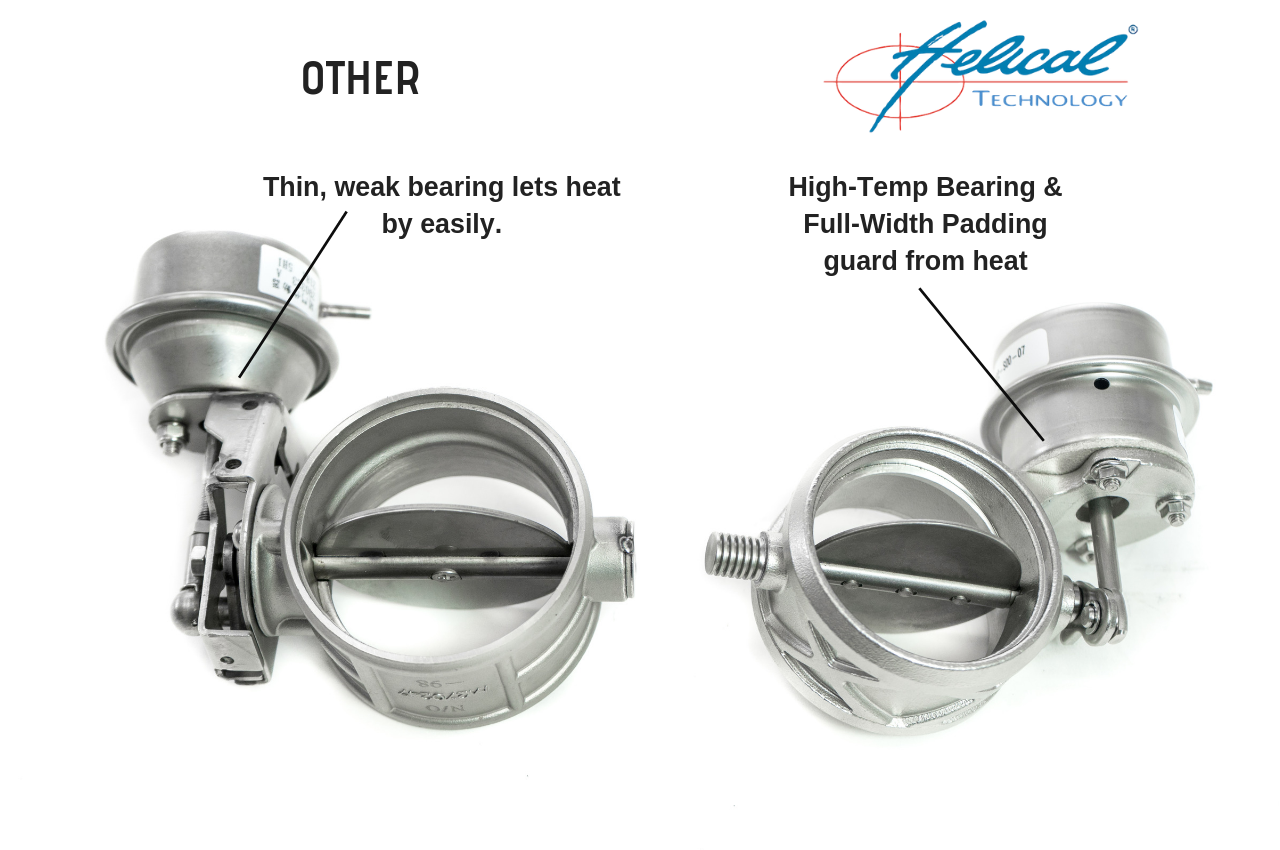

- Diaphragm Heat resistance: Helical valves include a thick, full-width heat shield to prevent heat from being conducted into the vacuum diaphragm housing, in addition, the diaphragm is made from a high-temperature silicone material. Why is this important in your exhaust valve? Heat that is conducted into the vacuum diaphragm housing will cause the diaphragm to degrade and eventually fail. Low-cost valves do not normally include heat shielding and often fail due to heat.

Helical exhaust valves are made to Aerospace Quality in Great Britain and are ISO 9001 certified for quality. Each and every step of Helicals manufacturing process is traceable. Helical exhaust valves were chosen by all the major OEM manufacturers like Porsche, Ferrari, Mclaren, Lamborghini, Aston Martin, and Jaguar Land Rover because the Helical valves are built to never fail and withstand the torture from daily driver use.

Canada

Canada

Euro

Euro

Australia

Australia

Pound

Pound

Peso

Peso

Singapore

Singapore

Bahraini Dinar

Bahraini Dinar

Malaysian Ringgit

Malaysian Ringgit

Qatar

Qatar

Russian Ruble

Russian Ruble